Hardness tester HardyTest D600©

Precise and practical

The HardyTest D600©, together with its brother the HardyTest D700©, belong to the upscale category in hardness-measurement instruments. It is designed to meet all requirements in the professional measurement of hardness.

The HardyTest D600© is applicable with almost all hardness measurements on ferrous and non-ferrous metals. It has proven its applications in the power industry, petrochemical industry, in apparatus-, automotive- and mechanical-engineering, quality control, steelwork industry, and many more.

Features and equipment

- 7 Impact device types (D , DC , DL , D + 15 , C , G and E) available for special applications; automatic identification on the device

- Large measuring range: 170-960 HLD (Leeb hardness testing principle)

- All hardness units: HL (Leeb), HB (Brinell), HRB (Rockwell B), HRC (Rockwell C), HV (Vickers), HS (Shore D)

- Simple and convenient operation

- Storage Capacity: 48 - 600 separate panels, each 1-32 measurements (contains the following information: date, average value, impact device, impact number, material, readings)

- Upper and lower limit can be set; Alarm signal when limits are exceeded

- Measurements at any angle (even upside down)

- Rapid tests by multiple measurement functions

- User calibration function

- Support rings (12 pieces) for convex and concave surfaces

- 128 x 64 dot matrix LCD: display of all functions and parameters + screen lighting

- PC-transfer with USB/RS232 cable and software

- Battery capacity display - 100 hours operating time (without backlight)

- Automatic shutdown (after 5 minutes) to save energy

Application

- Measurements on steel, cast steel, cold work tool steel, stainless steel, gray cast iron, nodular cast iron, cast aluminium alloys, brass, bronze and wrought copper alloys

- Measurements on large and small hollows, bearings, heavy parts, permanently assembled parts

- Defect analysis of pressure vessels, steam generators, etc.

- Material identification

Areas of application

- Production of metal and rubber components

- Mechanical engineering

- Research and development

- Solid state physics

Standard delivery range

- HardyTest D600© with impact device D

- Cleaning brush

- Testblock 800 HLD

- Small supporting ring

- Manual

- Service-case

- USB cable

- Software DataView on USB Stick

Optional accessory

- Other impact devices (for selection see "Impact devices")

- Set of supporting rings (see "Supporting rings")

- Printer

Downloads

Specifications

All SaluTron® gauges correspond to national (DIN) and international (ISO, BS, ASTM) norms and possess the CE-sign.

Specifications are subject to change without prior notice.

| Hardness units | HL (Leeb), HB (Brinell), HRB (Rockwell B), HRC (Rockwell C), HV (Vickers), HS (Shore D) |

| Measuring range | 170 – 960 HLD |

| Accuracy | ± 0,75 % (refered to HL = 800 ± 6 HL) |

| Measuring direction | 360° |

| Standard impact device | D |

| Memory size | 48-600 groups (relative to number of impact times 1-32) |

| Statistics | number of group, date, average value, impact device, impact times, material, measured values |

| Setting of limits | Acoustic signal by trespassing preset min. und max. limits |

| Minimum weight of sample | > 5 kg solid material; 2-5 kg on stable surface; < 2 kg with coupling paste on stable surface |

| Memory function | Manually oder automatically |

| Data transfer | 1 cable (both USB and RS232-connection) und software |

| Display | Dot-Matrix-LCD, 128 × 64 dots |

| Backlight | ON / OFF key |

| Battery capacity | 100 hours (without backlight) |

| Power supply | 2 x 1.5 Volt-AA-batteries |

| Auto Power-OFF | After 5 minutes |

| Relative humidity | ≤ 90% |

| Working temperature | -10°C to +40°C |

| Weight | 380 g (with batteries) |

| Size (length x width x height) | 125 x 67 x 30mm |

Impact devices

Specifications are subject to change without prior notice.

| Type of impact device | D, DC, DL | D+15 | C | G | ||

|---|---|---|---|---|---|---|

| Impacting energy | 11 mJ | 11 mJ | 2.7 mJ | 90 mJ | ||

| Mass of impact body | D+DC: 5.5 g DL: 7.2 g | 7.8 g | 3.0 g | 20.0 g | ||

| Test tip hardness | 1600 HV | 1600 HV | 1600 HV | 1600 HV | ||

| Dia. test tip | 3 mm | 3 mm | 3 mm | 5 mm | ||

| Material of test tip | Tungsten carbide | Tungsten carbide | Tungsten carbide | Tungsten carbide | ||

| Impact device diameter | 20 mm | 20 mm | 20 mm | 30 mm | ||

| Impact device length | D: 147 mm DC: 86 mm DL: 202 mm | 162 mm | 141 mm | 254 mm | ||

| Impact device weight | 50 g | 80 g | 75 g | 250 g | ||

| Max. hardness of sample | 940 HV | 940 HV | 1000 HV | 650 HB | ||

| Mean roughness value of sample surface Ra | 1.6 µm | 1.6 µm | 0.4 µm | 6.3 µm | ||

| Min. weight of sample | ||||||

| Measure directly | > 5 kg | > 5 kg | > 1.5 kg | > 15 kg | ||

| Needs support firmly | 2-5 kg | 2-5 kg | 0.5-1.5 kg | 5-15 kg | ||

| Needs coupling tightly | 0.05-2 kg | 0.05-2 kg | 0.02-0.5 kg | 0.5-5 kg | ||

| Min. thickness of sample | ||||||

| with tight coupling | 5 mm | 5 mm | 1 mm | 10 mm | ||

| Min. layer thickness for surface hardening | ≥ 0.8 mm | ≥ 0.8 mm | ≥ 0.2 mm | ≥ 1.2 mm | ||

| Size of tip indentation | ||||||

| Hardness 300 HV | Indentation diameter | 0.54 mm | 0.54 mm | 0.38 mm | 1.03 mm | |

| Depth of indentation | 24 µm | 24 µm | 12 µm | 53 µm | ||

| Hardness 600 HV | Indentation diameter | 0.54 mm | 0.54 mm | 0.32 mm | 0.90 mm | |

| Depth of indentation | 17 µm | 17 µm | 8 µm | 41 µm | ||

| Hardness 800 HV | Indentation diameter | 0.35 mm | 0.35 mm | 0.35 mm | - | |

| Depth of indentation | 10 µm | 10 µm | 7 µm | - | ||

| Available type of impact device | ||||||

| Impact device D | Universal device for most hardness requirements | |||||

| Impact device DC | Ultra-short version; manually loaded on the front; same characteristics as type D; for testing in boreholes, built-in parts, hollow cylindrical parts, etc. | |||||

| Impact device DL | With extremely long and fine front piece only for steel and cast steel; for testing in narrow or hard to reach areas | |||||

| Impact device D+15 | The front part is narrow and the coil is located behind it; same characteristics as type D; only for steel; for hardness testing in slots, grooves, recessed areas, gear flanks, grooves, cavities, tooth flanks, etc. | |||||

| Impact device C | Reduced impact energy of about ¼ of type D; for tempered or surface treated steel, small or sensitive-to-shocks parts (minimal imprint is left) | |||||

| Impact device G | With large test-tip diameter; impact energy 9 times larger than type D; on steel, gray or nodular cast iron; for large cast parts and forgings or parts with high surface roughness | |||||

| Type of impact device | Hardness value of standard Leeb hardness block | Error of displayed value | Repeatability of displayed value |

|---|---|---|---|

| D | 760±30 HLD 530±40 HLD | ±6 HLD ±10 HLD | 6 HLD 10 HLD |

| DC | 760±30 HLDC 530±40 HLDC | ±6 HLDC ±10 HLDC | 6 HLD 10 HLD |

| DL | 878±30 HLDL 736±40 HLDL | ±12 HLDL | 12 HLDL |

| D+15 | 766±30 HLD+15 544±40 HLD+15 | ±12 HLD+15 | 12 HLD+15 |

| G | 590±40 HLG 500±40 HLG | ±12 HLG | 12 HLG |

| C | 822±30HLC 590±40HLC | ±12 HLC | 12 HLC |

Test work pieces and hardness units

The ranges correspond to the limits applied in static test methods.

Specifications are subject to change without prior notice.

| Material | Hardness unit | Impact device | |||||

|---|---|---|---|---|---|---|---|

| D/DC | D+15 | C | G | E | DL | ||

| Steel and cast steel | HRC | 20-68.5 | 19.3-67.9 | 20.0-69.5 | - | 22.4-70.7 | 20.7-58.7 |

| HRB | 38.4-99.6 | - | - | 47.7-99.9 | - | - | |

| HB | 127-651 | 80-638 | 80-683 | 90-646 | 83-663 | 81-646 | |

| HV | 83-976 | 80-937 | 80-996 | - | 84-1042 | 80-881 | |

| HS | 32.2-99.5 | 33.3-99.3 | 31.8-102.1 | - | 35.8-102.6 | - | |

| Cold work tool steel | HRC | 20.4-67.1 | 19.8-68.2 | 20.7-68.2 | - | 22.6-70.2 | - |

| HV | 80-898 | 80-935 | 100-941 | - | 82-1009 | - | |

| Hammered steel | HB | 143-650 | - | - | - | - | - |

| Stainless steel | HRB | 46.5-101.7 | - | - | - | - | - |

| HB | 85-655 | - | - | - | - | - | |

| HV | 85-802 | - | - | - | - | - | |

| Grey cast iron | HRB | - | - | - | - | - | - |

| HB | 93-334 | - | - | 92-326 | - | - | |

| HV | - | - | - | - | - | - | |

| Nodular cast iron | HRC | - | - | - | - | - | - |

| HB | 131-387 | - | - | 127-364 | - | - | |

| HV | - | - | - | - | - | - | |

| Cast aluminum alloys | HB | 19-164 | - | 23-210 | 32-168 | - | - |

| HRB | 23.8-84.6 | - | 22.7-85.0 | 23.8-85.5 | - | - | |

| Brass | HB | 40-173 | - | - | - | - | - |

| HRB | 13.5-95.3 | - | - | - | - | ||

| Bronze | HB | 60-290 | - | - | - | - | - |

| Wrought copper alloys | HB | 45-315 | - | - | - | - | - |

Supporting rings

Specifications are subject to change without prior notice.

| No. | Code | Type | Sketch | Remarks |

|---|---|---|---|---|

| 1 | 03-03.7 | Z10-15 |  | For testing cylindrical outside surface R10-R15 |

| 2 | 03-03.8 | Z14.5-30 | For testing cylindrical outside surface R14.5-R30 | |

| 3 | 03-03.9 | Z25-50 | For testing cylindrical outside surface R25-R50 | |

| 4 | 03-03.10 | HZ11-13 |  | For testing cylindrical inside surface R11-R13 |

| 5 | 03-03.11 | HZ12.5-17 | For testing cylindrical inside surface R12.5-R17 | |

| 6 | 03-03.12 | HZ16.5-30 | For testing cylindrical inside surface R16.5-R30 | |

| 7 | 03-03.13 | K10-15 |  | For testing spherical outside surface SR10-SR15 |

| 8 | 03-03.14 | K14.5-30 | For testing spherical outside surface SR14.5-SR30 | |

| 9 | 03-03.15 | HK11-13 |  | For testing spherical inside surface SR11-SR13 |

| 10 | 03-03.16 | HK12.5-17 | For testing spherical inside surface SR12.5-SR17 | |

| 11 | 03-03.17 | HK16.5-30 | For testing spherical inside surface SR16.5-SR30 | |

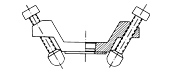

| 12 | 03-03.18 | UN |  | For testing cylindrical outside surface, radius adjustable R10-∞ |