Coating thickness gauges

For the non-destructive measurement of coating thickness on iron and non-ferrous metals

Measurement results with highest precision! SaluTron® Messtechnik GmbH is your specialist for precise working coating thickness gauges on iron and non-ferrous metals. Coating thickness measurement is an indispensable tool for quality assurance!

Coating thickness gauges from SaluTron®

Coating thickness gauges with integrated probe

The SaluTron ComBi-D3 combines coating thickness measurement on iron (Fe) and non-iron metals (NFe) in one device with an integrated Fe and NFe probe. If a coating thickness measurement is only desired on iron or non-iron metals, there is the SaluTron D4 (with integrated Fe probe) or the SaluTron D5 (with integrated NFe probe) as identical but more cost-effective alternatives.

The plus version adds a measurement value memory and the ability to transfer data to a PC for further data analysis.

As another cost-effective alternative, we offer you the combination gauge SaluTron ComBi-D1000 for measurements on steel and iron as well as on non-magnetic substrates.

Coating thickness gauges with external probe

The models SaluTron D1, D2X, and D6 find their individual areas of application in coating thickness measurement with external cable probes. The biggest advantage of the cable probe is the ability to measure the layer thickness in hard-to-reach places. The device D1 is the first choice for standard requirements.

If a measurement data storage for later transfer to the PC is required, the D2X coating thickness gauge provides a solution. Furthermore, the SaluTron D6 offers special probes for specific requirements: With the F10 probe, a layer thickness of up to 10,000 µm (10 mm) can be measured, or with the F1-90° angle probe, measurements can be taken at particularly tight and hard-to-reach areas.

Non-contact layer thickness measurement

In conclusion, the device CoatMaster Flex is the crown jewel in layer thickness measurement. The coating thickness gauge is capable of measuring the layer thickness on a variety of substrates without contact - allowing measurements to be taken during the coating process, identifying potential errors earlier, and optimizing material consumption efficiently.

Benefit from our many years of experience and comprehensive knowledge. Together we will find the right coating thickness gauge for your individual application. Please contact us. We are happy to advise you.

Product Overview

Product Comparison

| Model | Dimensions (B x H x T cm) | Weight (kg) | Measurement principle | Measuring range from…to | External/Integrated Probe | Data storage and data transmission? |

| SaluTron D1 | 1,5 x 8 x 3 | 0,15 | magnetic inductive / eddy current | Fe: 0 - 2000 µm nFe: 0 - 800 µm | External | No |

| SaluTron D2X | 1,2 x 6,5 x 2,2 | 0,26 | magnetic inductive / eddy current | Fe: 0 - 2000 µm nFe: 0 - 800 µm | External | Yes |

| SaluTron D4 | 1,2 x 5,8 x 3,8 | 0,15 | magnetic inductive | Fe: 0 - 5000 µm | Integrated | No |

| SaluTron D4Plus | 1,2 x 5,8 x 3,8 | 0,15 | magnetic inductive | Fe: 0 - 5000 µm | Integrated | Yes |

| SaluTron D5 | 1,2 x 5,8 x 3,8 | 0,15 | eddy current | nFe: 0 - 5000 µm | Integrated | No |

| SaluTron D5Plus | 1,2 x 5,8 x 3,8 | 0,15 | eddy current | nFe: 0 - 5000 µm | Integrated | Yes |

| SaluTron D6 | 1,3 x 6,5 x 3 | 0,34 | magnetic inductive / eddy current | Fe: 0 - 10.000 µm nFe: 0 - 1250 µm | External | Yes |

| SaluTron D6Plus | 1,3 x 6,5 x 3 | 0,34 | magnetic inductive / eddy current (combined) | Fe: 0 - 1500 µm nFe: 0 - 1500 µm | External | Yes |

| SaluTron ComBi D3 | 1,2 x 5,8 x 3,8 | 0,15 | magnetic inductive / eddy current (combined) | Fe: 0 - 3500 µm nFe: 0 - 3500 µm | Integrated | No |

| SaluTron ComBi D3Plus | 1,2 x 5,8 x 3,8 | 0,15 | magnetic inductive / eddy current (combined) | Fe: 0 - 3500 µm nFe: 0 - 3500 µm | Integrated | Yes |

| SaluTron ComBi D1000 | 1,2 x 6,5 x 2,7 | 0,12 | magnetic inductive / eddy current (combined) | Fe: 0 - 1250 µm nFe: 0 - 1250 µm | Integrated | No |

| CoatMaster | 9,1 x 20,3 x 37,4 | 2,0 | Advanced Thermal Optics | Wet paint: 1 - 400 µm Powder coating: 1 - 400 µm dry/burned: 1 - 1000 µm | Non-contact measurement | Yes |

Interesting facts about coating thickness gauges

Areas of application for coating thickness gauges

Coating thickness measuring devices are typically used in:

- paint shops

- electroplating shops

- car dealerships

- powder and paint coating

- automotive assessors and automotive insurance companies

- automotive industry

- workshops

- quality control

- bridge construction

- shipbuilding

- manufacturing process

- laboratory

- anodizing or galvanizing

- material testing in production as well as incoming and outgoing inspection

Coating thickness gauges from SaluTron

- Coating thickness gauges with integrated probe

- Coating thickness gauges with external probe

- Non-contact layer thickness measurement

- Coating thickness gauges with integrated probe

- Coating thickness gauges with cable probe

- Non-contact coating thickness measurement

Interesting facts about coating thickness gauges

- Areas of application for coating thickness gauges

- What can be measured with a layer thickness gauge?

- Characteristics of coating thickness devices

What can be measured with a layer thickness gauge?

A coating thickness gauge is primarily used to measure the layer thickness of paint and other coatings, sometimes also metallic coatings (usually in µm, possibly also in mm or mils). Two methods have become particularly established for this purpose, namely the magnetic inductive method and the eddy current method.

A coating thickness gauge using the magnetic inductive method is used to measure non-magnetic coatings such as paints, plastics, chrome, copper, zinc, enamel, etc. on steel or iron substrates. Devices using this method are abbreviated as Fe coating thickness gauges.

The coating thickness gauge using the eddy current method is used for measuring insulating coatings such as paint, enamel, plastic, paper, glass, rubber, as well as on non-magnetic metals such as aluminum, copper, brass, zinc, and certain types of stainless steel. It is also possible to measure anodized coatings on aluminum. Devices using this measurement method are referred to as nFe coating thickness gauges.

One disadvantage of the coating thickness gauges described above is that they are not suitable for all applications. For example, it is not possible to measure layer thickness on plastic substrates or wood. Measuring wet paint or powder coating is also a challenge. In order to offer a suitable coating thickness gauge for such applications, the CoatMaster was developed. This is the only model that operates using the innovative Advanced Thermal Optics method and enables contactless layer thickness measurement of, for example, wet paint on various substrates. Another advantage of this measurement method is the ability to perform precise measurements at extremely difficult-to-reach locations with unusual, uneven geometries.

Characteristics of coating thickness devices

Usually, there are coating thickness gauges available with either an integrated or external probe. The advantage of an external probe lies particularly in the ability to measure hard-to-reach areas. It should be noted that when using a new probe that has not been connected to the coating thickness gauge before, a new calibration must be performed. Typically, calibration foils are provided for this purpose. Self-calibration is of course not necessary for coating thickness gauges that are purchased together with a probe or have an integrated probe. It is only necessary to occasionally zero the gauge on an uncoated substrate.

Furthermore, coating thickness gauges, as described above, also differ based on the measurement method that determines the type of substrate on which measurements can be taken. However, there are so-called Combi (short for combination) devices that allow measurements on both types of substrates. The substrate is automatically recognized.

Additionally, some coating thickness gauges may also be equipped with an internal data memory. This is particularly appreciated by users who wish to document or analyze data on a PC.

When comparing coating thickness gauges, special attention should be paid to the measuring range and accuracy. These data are essential to determine if a coating thickness gauge can fulfill the required measurement task. Furthermore, additional functions such as a data memory and the ability for statistical data analysis can be important for many users. Another popular function of coating thickness gauges is the continuous measurement mode. This allows the gauge to be moved over a surface, observing the change in coating thickness in real-time. This can, for example, help determine if a vehicle has been repainted in a specific area. There are many other functions that a coating thickness gauge can be equipped with, such as two-point calibration, correction calibration, and more.

Lastly, the build quality of the device is also important. Well-made coating thickness gauges made from high-quality materials can last for decades, provide users with a pleasant feel, and can be easily and stably placed. Finally, a well-structured menu navigation ensures easy operation.

What should be considered when measuring layer thickness?

Preparation

Even before making a purchase, it is necessary to be clear about your requirements and measuring conditions. You should know the substrate under a coating, that is, whether the paint layer # is applied on steel or aluminum, for example. It is also important to know the material of the layer: Is it an organic, metallic, or plastic layer? Additionally, you should know in which measuring ranges you want to work and how accurately you need to take the measurements. If very precise measurements are required, not only the measurement accuracy of the coating thickness gauge itself plays a role. If measurements are to be taken on specific steel or aluminum alloys, the coating thickness gauge should also be able to store correction calibrations. This ensures that the ideal calibration is used for coating thickness measurements on alloys. This is necessary because the magnetic properties and conductivity of the alloys vary. If you want to measure under such specific conditions, we recommend contacting our competent service team by phone so that we can provide you with comprehensive advice on the topic of coating thickness gauge.

Example: A car dealer wants to be able to determine before purchasing a vehicle whether the vehicle in question has been repainted in some areas: He knows that the car paint will be measured on steel or aluminum. He is also aware that even a vehicle painted once has a layer thickness between 80 & 130 µm. Since the car dealer is only interested in determining whether the car has been painted once or multiple times, accuracy is of secondary importance to him. A measuring range of 1250 µm will certainly be sufficient.

Another example: An operator of an automated coating system is looking for a way to reduce costs. One option would be to optimize the paint consumption per coated part. This can be achieved by measuring the layer thickness during the coating process and adjusting the amount of paint in the coating system accordingly. The operator therefore needs a coating thickness gauge that measures the layer thickness non-destructively and contactlessly during the coating process.

As these two examples show, the conditions under which measurements are taken lead to completely different requirements for the coating thickness gauge. In the first case, a ComBi D3 or a ComBi D1000 would be completely sufficient. In the second case, the customer needs a CoatMaster Flex.

During the measurement of the layer thickness

You are aware of your measuring conditions. Ideally, you have consulted with experts, ordered and already received your optimal layer thickness measuring device. Now it is up to you to pay attention to the small details in order to carry out as precise layer thickness measurements as possible. If you are measuring on an alloy, you have informed yourself about the specifics for precise layer thickness measurements on alloys with our competent team.

To ensure as error-free measuring as possible with your new coating measuring device, please follow the instructions below:

- Make sure that the probe, the zero plate, and your workpiece are as free from dirt as possible. Otherwise, you will also measure the thickness of the dirt layer.

- Zero the device for layer thickness measurement on the zero plate corresponding to the substrate (e.g. Fe zero plate for measurements on steel).

- Make sure to place the probe as stable as possible. Lift the probe at least 2-3 cm from the surface.

- Check the zeroing by performing a measurement on the zero plate. The device should display 0.0. Otherwise, perform zeroing again.

- Perform multiple measurements on your workpiece. Make sure to always place the probe slightly offset (about 0.5 - 1 cm), unless you want to measure exactly one point.

- The measured values should generally only vary minimally.

Measuring methods used for coating thickness measurements

As with other surface measurement techniques, there are various methods for measuring layer thickness:

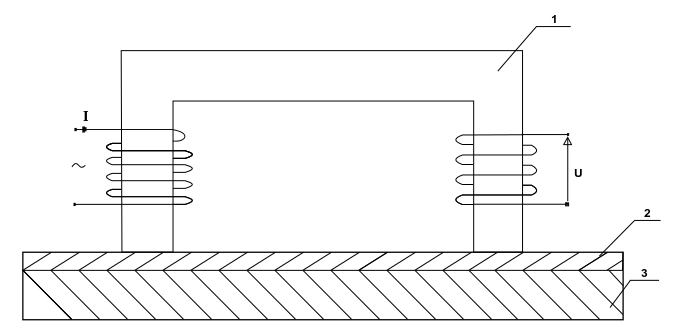

- The magnetic inductive method is an electromagnetic method for non-destructive material testing. It is used for measuring the thickness of magnetically neutral layers (such as paints, plastics, chrome, copper, zinc, enamel, etc.) on magnetic base material (iron/steel). The core of a test probe is a small transformer equipped with two windings. The primary winding is connected to the supply generator, while the secondary winding is connected to a measuring amplifier. During the measurement, the tested material becomes part of the transformer core, with the layer in between forming a gap in the core (Figure 1). Depending on the thickness of the layer, the magnetic resistance of the entire transformer changes, as does the electric voltage induced in the secondary winding. The amplitude of this voltage decreases non-linearly with increasing layer thickness (Figure 2). This effect is perceived by a layer thickness measuring device as a measurement signal and ultimately converted into a layer thickness. Since this measurement signal depends on the base material, a zeroing should be performed on the same uncoated base material before the measurement.

1 - Probe 2 - Layer 3 - Base material (iron or steel)

U - Measuring voltage D - Layer thickness

- Eddy current testing is an electrical method for non-destructive material testing. It is used for measuring the thickness of non-electrically conductive layers (such as paints, enamels, plastics, paper, glass, rubber, etc.) on non-magnetic, electrically conductive metals (e.g. aluminum, zinc, copper, brass). In this measurement method, an alternating magnetic field appears when a constant alternating current flows through a coil. The frequency of the generated magnetic field is the same as the alternating current and penetrates the tested material. If the material does not have electrical conductivity properties, the magnetic field remains unchanged. Otherwise, eddy currents are generated in the coated base material, which according to Lenz's law create a counter field and affect the overall impedance of the coil. The smaller the distance between the material and the coil, the greater the change in impedance (Figure 3). A layer thickness gauge determines the corresponding layer thickness from the change in impedance.

1 - Coil 2 - Eddy currents 3 - Base material (non-magnetic metal) 4 - Resulting current

- In the Advanced Thermal Optics (ATO) process, the surface of the coating is heated with a light pulse. After a short heating of a few degrees, this surface is cooled down into deeper areas of the coating and the substrate through heat conduction. The cooling process at the surface in turn depends on the thermal properties of the coating and the substrate. The thinner the coating, the faster the surface temperature drops. The thickness and thermal properties of the coating are calculated from the dynamics of the surface temperature.