Hardness tester HardyTest 1800B©

The hardness tester HardyTest 1800B©enables our clients to take measurements even at small and hard accessible points (e.g. tooth flanks). Through its small constructions it is easy to carry and always right at hand. Nevertheless it fulfills all requirements of a modern hardness tester.

Characteristics

- 2 in 1 impact device D + DL for measurements on small and hard accessible points

- Mountable DL probe (Ø 4 mm, length 50 mm)

- Large measurement range

- Easy to calibrate

- Very large memory

- Re-chargable battery

- Applicable under extrem conditions (-40°C to 80°C)

- Statistical analysis of mean, min and max value

- Display, print and delete values (printing through bluetooth printer)

- Datatransfer to PC

- Software for data analysis

Application

- Measurements on steel, cast iron, tool steel, stainless steel, gray and ductile iron, brass, bronze, aluminum and wrought copper alloys

- Measurements on large and small molds, bearings heavy workpieces, and permanently assembled parts

- Failure analysis of pressure vessels, steam generators, etc.

- Material identification

Areas of application

- Production of metal and rubber components

- Mechanical engineering

- Research and development

- Solid state physics

Standard delivery range

- HardyTest 1800B© with integrated impact device type D

- Mountable impact device type DL

- Test block

- Brush

- 3.7 V re-chargable battery

- USB cable

- Certificate

- Battery charger

- Operation manual

- Carrying case

Optional

- Bluetooth printer

- Cable for printer

- 12 supporting rings (convex/concave)

Specifications

All SaluTron® gauges correspond to national (DIN) and international (ISO, BS, ASTM) norms and possess the CE-sign.

Specifications are subject to change without prior notice.

| Hardness unit | HL (Leeb), HB (Brinell), HRB (Rockwell B), HRC (Rockwell C), HV (Vickers), HS (Shore D), σb breaking stress |

| Measurement range | 170-960 HLD / 80-940 HV (on steel) |

| Materials | Steel/cast steel, tool steel, stainless steel, gray iron, spheroidal iron, aluminium alloys, brass, bronze, copper |

| Accuracy | ±6 HL at HL = 800 |

| Radius workpiece | D: min. 20 mm, DL: min. 4 mm |

| Min. weight of working piece | 5 kg; 2-5 kg on stable base; 2 kg with coupling paste |

| Min. thickness of working piece | 3 mm with coupling paste |

| Min. roughness of working piece | 1,6 µm (Ra) |

| Min. hardness depth | 0,8 mm |

| Penetration depth | 300 HV=24 µm, 600 HV=17 µm, 800 HV=10 µm |

| Measurement directions | 0 - 360° |

| Functions | Value corrections and calibration, setting of impact device, material, hardness unit and measurement direction, automatic on/off, alarm at set min/max value |

| Statistics | Display of mean, max and min |

| Memory | 4 blocks of 4000 values |

| Datatransfer to PC | Via USB, Analysis via Software |

| Display | OLED-Display, lighting adjustable |

| Power supply | 3,7 V re-chargable battery |

| Mesurement conditions | -40°C to 80°C, ≤ 80% rel. humidity |

| Standards | GB/T 17394-1998, ASTM A956, DIN 50156 |

| Dimensions | 148 x 44 x 22 mm, lenght of impact device DL: 205 mm |

| Weight | 110 g |

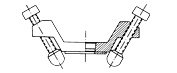

Backup rings

Subject to change

| No. | Code | Type | Drawing | Application |

|---|---|---|---|---|

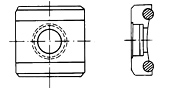

| 1 | 03-03,7 | Z10-15 |  | Measurements on outer cylindrical surfaces R10-R15 |

| 2 | 03-03,8 | Z14,5-30 | Measurements on outer cylindrical surfaces R14,5-R30 | |

| 3 | 03-03,9 | Z25-50 | Measurements on outer cylindrical surfaces R25-R50 | |

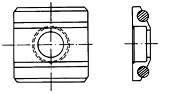

| 4 | 03-03,10 | HZ11-13 |  | Measurements on interior cylindrical surfaces R11-R13 |

| 5 | 03-03,11 | HZ12,5-17 | Measurements on interior cylindrical surfaces R12,5-R17 | |

| 6 | 03-03,12 | HZ16,5-30 | Measurements on interior cylindrical surfaces R16,5-R30 | |

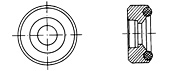

| 7 | 03-03,13 | K10-15 |  | Measurements on spherical outer surfaces SR10-SR15 |

| 8 | 03-03,14 | K14,5-30 | Measurements on spherical outer surfaces SR14,5-SR30 | |

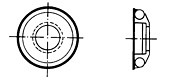

| 9 | 03-03,15 | HK11-13 |  | Measurements on spherical interior surfaces SR11-SR13 |

| 10 | 03-03,16 | HK12,5-17 | Measurements on spherical interior surfaces SR12,5-SR17 | |

| 11 | 03-03,17 | HK16,5-30 | Measurements on spherical interior surfaces SR16,5-SR30 | |

| 12 | 03-03,18 | UN |  | Measurements on outer cylindrical surfaces, radius adjustable R10-∞ |