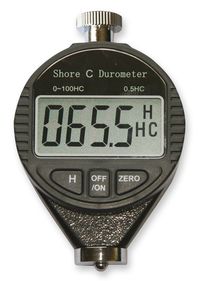

Hardness tester Shore C Durometer

- Applies to rubber and contains the tiny hole material that the vesicant is made for being used in plastics

- For testing the hardness of shoe-making porous materials made by vesicants within plastics when the compression rate is 50 % and stress is beyond 0.049 MPa.

- Stress at the end of pointer: 0.55 N – 8.06 N

- 0 – 100 HC

- 0.5 HC

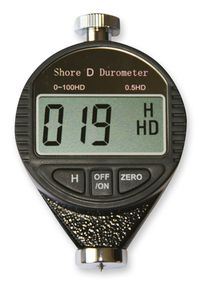

Standard delivery range

- Durometer A, C or D

- Battery

- Instructions manual