Hardness tester HardyTest D100©

The instrument is very small and manageable so that it can be optimally used for large and narrow pieces.

The HardyTest D100© is applicable with almost all hardness measurements on ferrous and non-ferrous metals. It has proven itself in the power industry, petrochemical industry, in apparatus-, automotive- and mechanical-engineering, quality control, steelwork industry, and many more.

The measuring principle of the HardyTest D100© is defined as the quotient of the rebound and impact speed of the impact body multiplied by 1000. During the material test the impact body is knocked by the elastic force with a spherical calotte from hard metal against the tested surface causing a rebound off the impact body. The instrument measures the impact and rebound speed so that the permanent magnet installed in the impact body passes through a coil during the test and induces electric currents that behave proportionally to the speeds. The measured values, based on the impact and rebound speed, are calculated by the instrument to form the hardness value.

Characteristics and equipment

- Rugged handheld instrument

- Integrated impact device

- Small, handy, ideal for measurements on rough parts

- Easy handling

- For all metallic materials

- Large measuring range: 200 - 960 HL

- Measurements in any position

- All hardness units: HL (Leeb), HB (Brinell), HRA (Rockwell A), HRB (Rockwell B), HRC (Rockwell C), HV (Vickers), HS (Shore)

- High accuracy: ± 0.6 % at HL = 800 (HRC0.2)

- Automatic power off

- Recalibration possible

- Support rings (12 pieces) for convex and concave surfaces

- Execution by ASTM standard

Application

- Measurements on steel, cast iron, tool steel, stainless steel, gray and ductile iron, brass, bronze, aluminum and wrought copper alloys

- Measurements on large and small molds, bearings, heavy workpieces, and permanently assembled parts

- Failure analysis of pressure vessels, steam generators, etc.

- Material identification

Areas of application

- Production of metal and rubber components

- Mechanical engineering

- Research and development

- Solid state physics

Standard delivery range

- HardyTest D100©

- Built-in impact device type D

- Test block D

- Battery charger

- Battery

- Robust plastic transport case

- Cleaning brush

Optional accessory

- Set of backup rings for measurements on convex surfaces with a radius of less than 30 mm. Makes optimal positioning on the test piece easier. The corresponding caps are screwed on the impact device front. Can be supplied for 12 different radii.

Specifications

All SaluTron® gauges correspond to national (DIN) and international (ISO, BS, ASTM) norms and possess the CE-sign.

Specifications are subject to change without prior notice.

| Display | LCD, 10 mm high |

| Precision | ± 0,5 % (refered to HL = 800 ± 4 HL) |

| Measurement range | from 200 to 960 HL |

| Display of measured hardness | HL / HRC / HRB / HB / HV / HC |

| Materials | 9 different general materials |

| Memory | 99 measured values |

| Impact device | type D |

| Power supply | DC 9V |

| Dimensions (L x W x H) | 100 x 60 x 33 mm |

| Weight | 150 g, weight with case and test body etc. = 4.3 kg |

Test work pieces and hardness units

Specifications are subject to change without prior notice.

| Test work pieces | Hardness units | |||||

|---|---|---|---|---|---|---|

| HL | HRC | HRB | HB | HV | HS | |

| Steel/cast steel | 174-960 | 19-68 | 38-100 | 80-683 | 80-1027 | 32-102 |

| Tool steel, cold rolled | 20-67 | - | - | 80-900 | - | |

| High-grade steel | 20-62 | 46-102 | 80-655 | 85-800 | - | |

| Cast iron | - | - | 93-334 | - | - | |

| Spheroidal graphite iron | - | - | 130-390 | - | - | |

| Aluminium cast alloys | - | - | 20-160 | - | - | |

| Copper/zinc alloys (brass) | - | 13-95 | 40-173 | - | - | |

| CuA1/, CuSn-alloys (bronze) | - | - | 60-290 | - | - | |

| Forgeable copper alloys | - | - | - | - | - | |

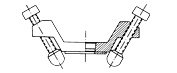

Backup rings

Subject to change

| No. | Code | Type | Drawing | Application |

|---|---|---|---|---|

| 1 | 03-03,7 | Z10-15 |  | Measurements on outer cylindrical surfaces R10-R15 |

| 2 | 03-03,8 | Z14,5-30 | Measurements on outer cylindrical surfaces R14,5-R30 | |

| 3 | 03-03,9 | Z25-50 | Measurements on outer cylindrical surfaces R25-R50 | |

| 4 | 03-03,10 | HZ11-13 |  | Measurements on interior cylindrical surfaces R11-R13 |

| 5 | 03-03,11 | HZ12,5-17 | Measurements on interior cylindrical surfaces R12,5-R17 | |

| 6 | 03-03,12 | HZ16,5-30 | Measurements on interior cylindrical surfaces R16,5-R30 | |

| 7 | 03-03,13 | K10-15 |  | Measurements on spherical outer surfaces SR10-SR15 |

| 8 | 03-03,14 | K14,5-30 | Measurements on spherical outer surfaces SR14,5-SR30 | |

| 9 | 03-03,15 | HK11-13 |  | Measurements on spherical interior surfaces SR11-SR13 |

| 10 | 03-03,16 | HK12,5-17 | Measurements on spherical interior surfaces SR12,5-SR17 | |

| 11 | 03-03,17 | HK16,5-30 | Measurements on spherical interior surfaces SR16,5-SR30 | |

| 12 | 03-03,18 | UN |  | Measurements on outer cylindrical surfaces, radius adjustable R10-∞ |